-

Product Development

Collaborative innovation through the whole industry chain of upstream and downstreamAnd that safety, the energy density, the pow density and the service life of the anode material are comprehensively improved.-

Raw Material Design

Through the regulation and control of the molecular structure and composition of raw materials, the customization of special coke for high-quality anode is realized.

-

Powder Design

Regulating the surface microstructure and particle size distribution of the powder particles to achieve the best electrical performance

-

Material Customization

The full index of anode materials can be customized to meet the application needs of customers in all scenarios.

-

-

Process Development

Large industrial model is established by using large production data to study the relationship between process conditions and material properties.Realize the digital transformation of process manufacturing-

Power Transmission Curve Design

Original Ouyang Curve in the industry, leading in quality, energy consumption and timeliness

-

Front-end Equipment Integration

Large-scale comminution and granulation integrated equipment can synchronously improve the yield and reduce the energy consumption

-

Gradient Coating

Multi-layer gradient coating to realize precise guidance of interface ions and high-speed shunt

-

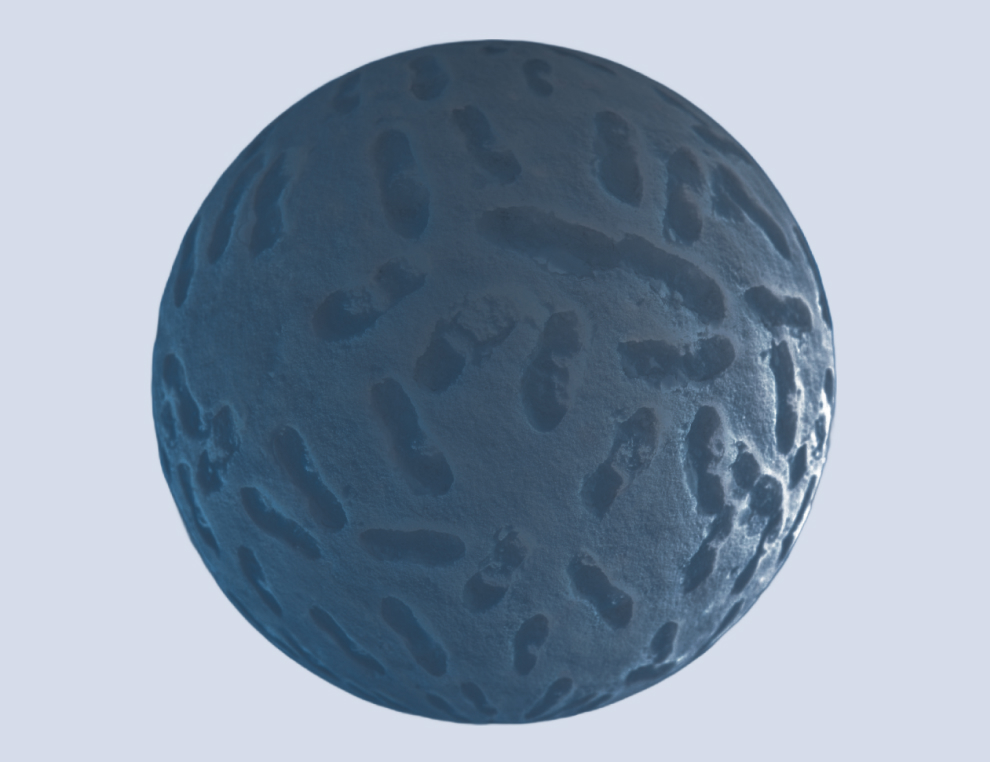

Surface Etching

Construct multi-channel ion transport highway to achieve low decay of the whole process of dynamics

-

-

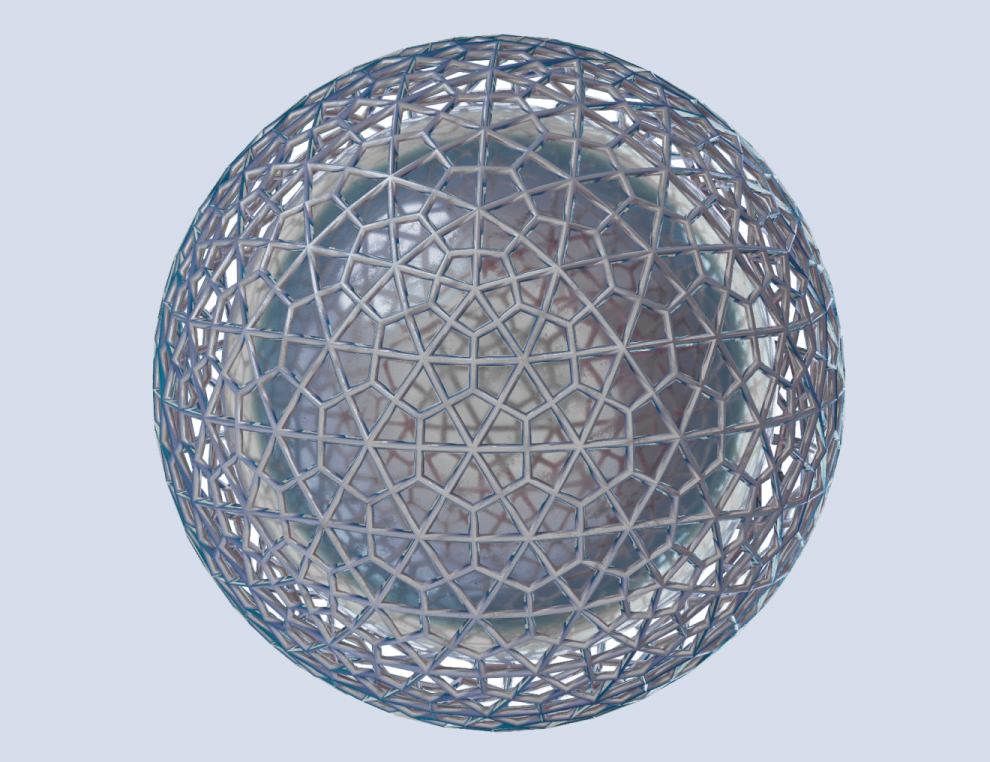

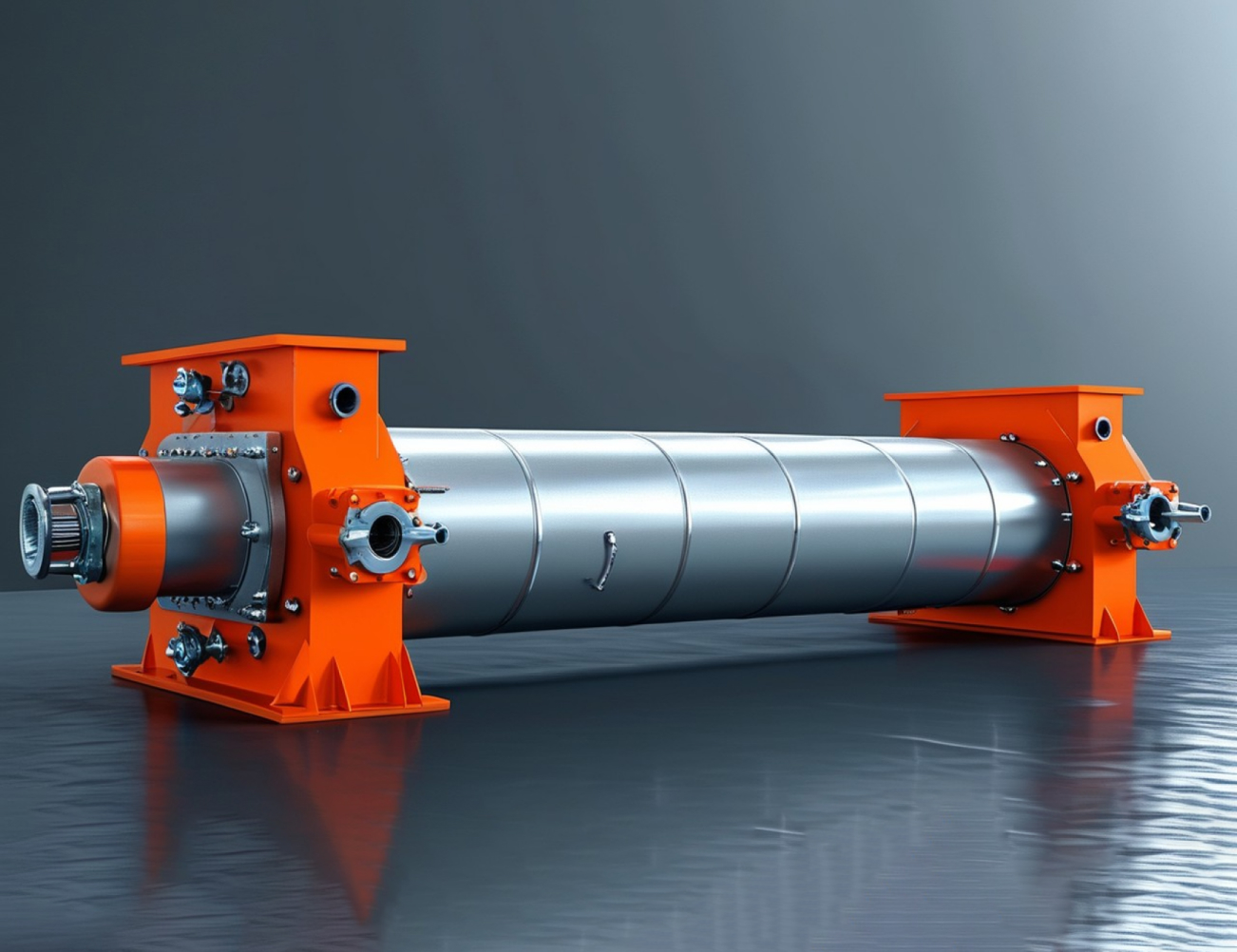

Equipment Development

Develop large-scale, continuous and intelligent new advanced manufacturing equipment with the help of first principle and interdisciplinary equipment development concept-

Large Intelligent Devices

Develop large-scale intelligent processing equipment to realize 2.0 upgrade of industrial intelligent manufacturing of graphite anode

-

Ultra-High Temperature Furnace Design

Support 1800 ℃ high temperature amorphous carbon layer repair and graphitization high temperature waste heat conduction development

-

Mechanical Cycle Fusion Machine

The interface optimization and high density of the material are realized by physically fusing the surface of the negative electrode material

-

-

Product Development

-

Process Development

-

Equipment Development